Ask a Question or Request a Quote

Talk to an expert today

Brinell Hardness Test vs Rockwell

By Engaged Expert

Lee ManghamLee Mangham是谢菲尔德im体育APP实验室的技术经理, 他负责各种各样的技术内容,并拥有超过30年的机械测试经验.

硬度测试是评价材料最广泛使用的方法之一. Among the various techniques available, 布氏硬度和洛氏硬度测试是评估金属硬度和耐磨性的最常用方法. In this article, our seasoned expert, Lee Mangham, 会告诉你布氏硬度测试和洛氏硬度测试的区别吗, including their methods, advantages, differences, and practical significance in evaluating material hardness.

布氏硬度试验和洛氏硬度试验有什么区别?

虽然这两个测试有相似之处,但也有一些重要的区别. 两种测试方法都适用于软、中硬材料(如铝)的测试, Cu alloys, and soft steel. Whilst Brinell’s method can test any type of metal, it is unable to measure hardness greater than 650 HB.

洛氏测试被认为更容易执行,与通常需要30-60秒的布氏测试程序相比,洛氏测试的总测试时间更短,只有10-15秒.

许多人认为布氏法的结果更准确和可靠, especially when testing coarse materials, as the spherical indenter distributes pressure more evenly. In the Rockwell test, if the hardness of the sample is not uniform, three indents will measure the average hardness of the sample, which can affect overall accuracy.

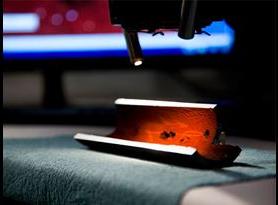

What is The Brinell Hardness Test?

布氏硬度试验(HBW)是量化材料硬度的重要指标, defined in ASTM E10 and BS EN ISO 6506-1 standards.

该试验包括在规定的载荷和持续时间下将布氏压头压在试样上. Typically, a hardened Tungsten steel ball, with varying force ranges based on material type and ball diameter, is employed for indentation. 负载应用时间跨度为10至15秒,确保稳定性和准确性. Subsequently, the resultant indentation is meticulously measured.

布氏试验是用显微镜测量压痕的宽度. 然后使用布氏硬度标度将该测量值转换为布氏硬度值——施加力与压痕表面之间的比率.

Some of the advantages of the Brinell Hardness Test include:

- Simple surface preparation

- Easy measurement of the print diameter

- 与罗克韦尔测量相比,更精确的最终测量

- Reduced risk of testing delays due to equipment failure, 特别是与洛氏试验中金刚石锥体破裂的可能性形成对比

“我们发现,如果客户需要高度精确的结果,并且没有指定的硬度方法,布氏硬度测试通常是我们首选的测试方法.”

Lee Mangham

Technical MANAGER

What is The Rockwell Hardness Test?

洛氏硬度试验是用洛氏硬度标度测量的 ASTM E18 and BS EN ISO 6508-1.

洛氏硬度试验是用规定尺寸的压头,以规定的力施加固定的时间进行的. 小钨钢球(HRBW方法)用于穿透软质材料,而金刚石锥(HRC方法)用于穿透较硬和热处理的材料.

在施加主载荷之前,测试使用预载荷来建立零位置. The main load is then taken away, leaving just the preload. 然后洛氏测试设备测量穿过材料的距离.

Unlike the Brinell method, Rockwell’s method does not measure the size of the imprint, but the depth of the indentation. 然后在机器上直接将测量值转换为洛氏硬度值.

Some of the advantages of the Rockwell hardness test include:

- 比需要决策的布氏试验方法更简单的计划阶段, such as the selection of the appropriate force, to be made

- 更快的结果,在洛氏装置上立即读取硬度

- 与30-60秒布氏测试程序相比,测试时间缩短至10-15秒

- 与布氏试验方法相比,该方法对试样或材料的损伤较小,只留下一个浅的印记,而布氏试验方法留下一个大的印记, visible trace.

Brinell Hardness To Rockwell Conversion

洛氏硬度和布氏硬度的换算尺度在非奥氏体钢和奥氏体钢之间是不一致的,不应相互混淆. 因此,在比较布氏硬度和洛氏硬度时要非常小心. ASTM E140给出了两种硬度类型和材料类型以及其他如维氏和努氏硬度之间的转换表. 同样重要的是要注意,所有的硬度转换都是近似值.

选择最适合材料性能及其预期应用的测试, 然后仔细遵循正确的测试方案和程序, are the two most important ways to ensure reliable results.”

Lee Mangham

Technical MANAGER

Conclusion

布氏硬度和洛氏硬度试验是一种有价值的评定方法 material hardness, each with its own advantages and considerations. While the Rockwell test offers simplicity and faster results, 布氏试验因其公认的准确性和可靠性而受到青睐, particularly with coarse materials. Ultimately, 这些方法之间的选择取决于测试场景的具体要求和被评估材料的特性.

在Element,我们提供布氏硬度和洛氏硬度测试作为其广泛产品组合的一部分 mechanical testing services. Element的实验室可以协助定制或复杂的设置,以满足特定的需求和要求, with our experts guiding you through the entire process, 从选择和管理最合适的测试程序到评估结果. For more information on hardness testing, please contact Element today.

Find related Resources

More from Element

Hardness Testing

Element的实验室使用各种微压痕和宏观压痕测试方法来确定材料对变形的硬度.

What is Hot Hardness Testing?

As the only commercial laboratory offering hot hardness testing, Element's experts are at the forefront of this unique technology.

Mechanical & Destructive Testing

Element的机械测试是我们破坏性测试服务的一部分, 它们表明材料或部件是否适合其预期的机械应用.

Failure Analysis

了解Element的全球故障分析专家团队如何从过去中吸取教训, to help prevent failures in service.