Element is a global network of corrosion testing labs and a recognized world leader in the provision of corrosion testing services within the Oil & Gas industry. We provide effective programs to help reduce the cost of material failure and ensure that your assets are safe and will perform as expected once deployed.

With a global platform of corrosion testing services in the US, UK, Europe, the Middle East, and Asia, we have the right combination of technical expertise, capabilities, and accreditations to support the oil and gas sector.

Our corrosion experts follow international testing standards and protocols such as ASTM, NACE, and API. We can assist you with a wide range of corrosion testing services and evaluations, material selection, corrosion assessments, recommending efficiencies, and preventative mitigation measures.

Corrosion testing service capabilities

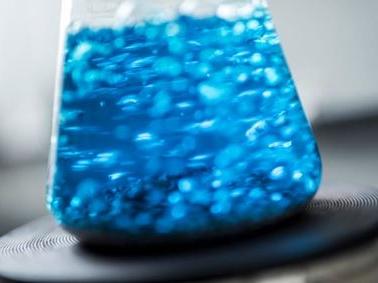

Our global corrosion testing offers a full range of services, including pipeline corrosion testing for sour and non-sour applications. We provide our customers with real-life data on how the materials are likely to perform in specific conditions and inform their design, materials, or chemical selection decisions.

Our corrosion labs are fully accredited to test both metallic and non-metallic materials, specializing in the qualification of “sour” service applications such as Hydrogen Induced Cracking (HIC) or Sulfide Stress Cracking (SSC).

Oil and gas corrosion services

We are proud to be among the world’s most trusted corrosion testing companies, and can assist you with corrosion analysis services for a range of applications. Staying at the forefront of corrosion testing, our engaged experts are continually developing new and innovative testing methods, such as SOHIC testing and Axial Full Ring testing under longitudinal tensile load.

The Element advantage

Through expert analysis of simulation exposure data, we help our customers to reduce the future risk of corrosion damage to pipelines and other critical infrastructure assets. You can make certain that assets are fully utilized for their optimum service life and safety in oil and gas operations.

To request a quote for our corrosion testing services, contact us today.

Predicting component life with corrosion modeling

Erosion within oil and gas pipelines is a serious problem. Corrosion modeling using the Computational Fluid Dynamic method can accurately predict the location of burn-throughs.

Read MoreWebinar: Corrosion of Stainless Steel

This webinar shows examples of corrosion damage and guides you through how to avoid corrosion in your stainless steel products to prevent product failure and costly repairs.

Watch NowWebinar: Criticality of Failure Analysis in the Energy Industry

Element’s experts for Failure Analysis in the Energy industry explain during the on-demand webinar how Failure Analysis is being performed, and its benefits by providing real-life case studies from around the world.

Read MoreFeatured Services

Element offers the most comprehensive range of corrosion testing services for the Oil & Gas sector.

Pitting & Crevice Corrosion Testing

Element’s ASTM G48 corrosion testing ensures the quality of material and resistance to pitting and crevice corrosion in ambient, elevated pressure and chloride environments.

Sulfide Stress Cracking (SSC) Testing

Element's SSC (Sulfide Stress Cracking) testing according the NACE TM0177/ ISO 15156 standard helps ensure sour service pipelines’ reliability and longevity.

Hydrogen Induced Cracking (HIC) Testing

Element’s HIC tests evaluate material susceptibility to hydrogen induced cracking in a sour environment in accordance with NACE TM0284.

Corrosion Under Insulation (CUI) Testing

Element supports clients to assist in evaluating solutions to try and mitigate corrosion under insulation (CUI).

Electrochemical Corrosion Testing

Element provides electrochemical corrosion testing using Electrochemical Impedance Spectroscopy, cyclic potentiodynamic polarization measurements and galvanic corrosion measurements.

Intergranular Corrosion (IGC) Testing

Element offers a variety of intergranular corrosion testing services for stainless steels, nickel alloys and aluminum alloys metallic, including testing per ASTM A262, ASTM G28 and G67.

Sour Service Corrosion Testing

Element is one of a few ISO certified sour service labs in the world, providing sour service corrosion services for a variety of test types including NACE MR0175/ISO 15156.

High Pressure High Temperature (HPHT) Testing

Element offers an advanced HPHT testing program for polymers, metals, coatings and components used in highly aggressive environments.

Stress Corrosion Cracking (SCC) Testing

Element’s Stress Corrosion Cracking (SCC) testing evaluates the susceptibility of metals to cracking failure under tensile stress and corrosion.

Hydrogen Embrittlement Testing

Element performs Hydrogen Embrittlement (HE) testing to ASTM F591, Galvanically Induced Hydrogen Stress Cracking (GHSC) to NACE MR0175/ISO 15156 and Hydrogen Induced Stress Cracking (HISC) testing.

Galvanic Corrosion Testing

Element offers galvanic corrosion testing to ASTM G71, ASTM G82 and to clients' specific standards to help select the right material combinations for an application.

Corrosion Inhibitor Testing

Element’s corrosion inhibitor testing experts select the most suitable corrosion inhibitor to protect your assets and extend their life span within the energy industry.